INSIDE THE FACTORY M&M'S MAKING MACHINES |

|

|

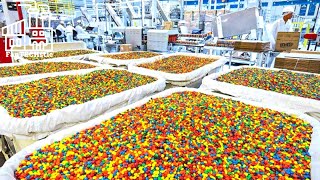

The Manufacturing Process of M & M® Candy

Molding : 1 The liquid chocolate is poured into tiny molds to create the chocolate centers of the candy. (If they are peanut or almond M&Ms, the chocolate surrounds a whole peanut or almond. For peanut butter chocolate M&Ms'the peanut butter center is made first, and then surrounded by the chocolate. The production process that follows is essentially the same for all varieties.) 2 After the candies are formed, they are "tumbled" to make the chocolate center smooth and rounded. Then they are allowed to harden. Coating 3 When the chocolates are hard, they are transported via conveyor belt to the coating area, where the process called panning is performed. 4 During panning, the chocolates are rotated in large containers as liquid candy made of sugar and corn syrup is sprayed onto them. The coats are sprayed on rotating chocolates at timed intervals. These intervals allow each coat to dry. Each coat leaves an even layer, a shell, of dry candy substance. The chocolate centers receive several coatings to ensure a uniform, complete coat on every piece. 5 The color is added to a finishing syrup and applied as the final coat. Each batch is a different color. Finally, the liquid candy dries into the hardened shell. Printing 6 The single-colored batches are combined into the mixtures of red, yellow, blue, green, brown, and orange. They are then transported to the machine that stamps the "m" on the shells. A special conveyor belt carries the pieces to this machine. Each piece rests in its own indentation. The piece runs under rubber etch rollers that gently touch each candy to print the "m." This machine is specially designed to imprint the "m" without cracking the thin candy shell. The process used is similar to the off-set printing process. Approximately 2.6 million M&Ms' are transported to the etching machine per hour. One hundred million individual M&Ms® can be manufactured per day. Packaging 7 A special packaging machine weighs the candies, pours the proper amount into individual bags, and heat-seals the package. Plain M&Ms' are proportioned (approximately) as follows: 30% brown; 20% yellow; 20% red; 10% green; 10% orange; 10% blue. Peanut M&Ms' are 20% brown; 20% yellow; 20% red; 20% blue; 10% green; and 10% orange. Peanut Butter Chocolate M&Ms® and Almond M&Ms® have even proportions (20% each) of yellow, red, green, blue, and brown. 8 The finished packages are moved along a conveyor belt to a machine that assembles the shipping cartons and fills them with the appropriate number of candy packages. The machine also seals the cartons shut. 🔔 Thanks for watching my videos, please leave feedback if you enjoyed, and subscribe for more interesting videos! https://www.youtube.com/channel/UCqOu70migtMqMQf-5GwYuiA?sub_confirmation=1 ▶Note: All of these videos are licensed or used with permission from the original video owner. For any inquiries, please contact us ✉: Ot112mane@gmail.com Happy Days In Summer by MusicLFiles Link: https://filmmusic.io/song/8020-happy-days-in-summer A Happy Smile On Your Face by MusicLFiles Link: https://filmmusic.io/song/7983-a-happy-smile-on-your-face A Successful Company by MusicLFiles Link: https://filmmusic.io/song/7966-a-successful-company License: https://filmmusic.io/standard-license |