3 Steps to Better Kaizen |

|

|

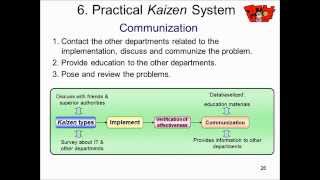

The underlying philosophy of Kaizen is that unless a process is improving, it is degrading. This means that every process needs to have an improvement plan. And it’s part of everyone’s job to make this happen by suggesting improvements and working on them.

Sounds great, right? Not so fast. Could the very need for Kaizen be a red flag, a warning that something was lacking at the design stage? It’s easy to embrace the concept of Continuous Improvement, without considering why you need it to begin with. The problem with traditional Kaizen is that continuously improving a broken system results in wasted time, resources, and money. What I’m proposing is a new approach to Kaizen. Rather than seeking to incrementally improve your Current State, begin with the end in mind. Then use your Kaizen efforts, not as a quick fix, but as a means towards the creation of the perfect Value Stream. Free Webinar: 3 Steps to Better Kaizen I'll be hosting an hour long webinar on the subject next Tuesday (August 8) it's free to attend. You can sign up for it at the link above. |

![[Toyota Production System] Just-in-Time: The Pull System](https://ytimg.googleusercontent.com/vi/HIEufX83EEY/mqdefault.jpg)